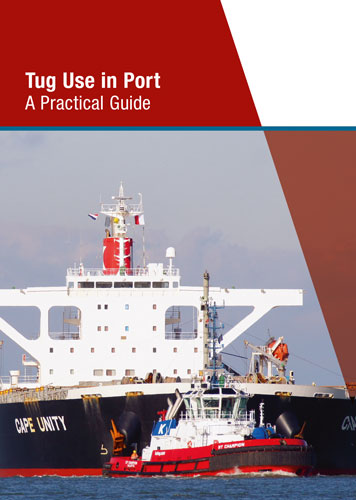

Tug Use in Port. A Practical Guide/Использование буксиров в порту. Практическое руководство

Издание на английском языке

One of the most delicate responsibilities of pilots occurs during berthing and unberthing operations. Carefully berthing a ship, often after a long pilotage mission, is almost a work of art. Of critical assistance in this task is the support of tugs and their skippers. Today, this is probably true more than ever, as ships become ever larger, e.g., ultra large container vessels with their huge windage, while often being significantly less powerful or able to manoeuvre themselves in confined waters. These vessels may have proportionately smaller rudders coupled with engines that, often deliver less power, notably as a result of software-managed fuel consumption.

Contents

Foreword

Author’s preface

Acknowledgements

Glossary of terms

Tug Use in Port : The Overview

Chapter 1: Tug design factors

1.1 Differences in tug design and assisting methods

1.2 Factors influencing tug type and tug assistance

1.3 Types of tug

1.4 Assisting methods

1.5 Conclusion

Chapter 2: Types of harbour tug

Part A: Classification of tugs and operational design aspects

2.1 Classification of basic harbour tug types

2.2 Important general requirements for good tug performance

Part B: Basic tug types

2.3 Conventional types of tug

2.4 Combi-Tugs

2.5 Tractor tugs with cycloidal propellers

2.6 Tractor tugs with azimuth propellers

2.7 Reverse-tractor tugs

2.8 Japanese tug concept

2.9 Azimuth Stern Drive (ASD) tugs

2.10 Uni-lever system

Part C: Related tug types

2.11 Rotortug

2.12 Z-tech tug

2.13 RSD tug

2.14 Carrousel tug

2.15 DOT tug

2.16 The All-Rounder AR360T

Part D: Fast tug types

2.17 Introduction

2.18 SDM (Ship Docking Modules)

2.19 Eddy

2.20 Carrousel RAVE Tug (CRT)

2.21 Giano tug

Part E: Specific Tugs. Research. Performance

2.22 Tugs handling LNG carriers. LNG terminal tugs

2.23 Eco- tugs

2.24 Ice tugs

2.25 Research

2.26 Tug performance

Chapter 3: Assisting methods

3.1 Introduction

3.2 Assisting methods

3.3 Tug assistance in ice

3.4 Assisting Navy ships

Chapter 4: Tug capabilities and limitations

4.1 Introduction

4.2 Basic principles and definitions

4.3 Capabilities and limitations

4.4 Design consequences

4.5 Environmental limits for tug operations

4.6 Conclusions regarding tug types

4.7 Some other practical aspects

Chapter 5: Bollard pull required

5.1 Introduction

5.2 Factors influencing total bollard pull required

5.3 Bollard pull required

Chapter 6: Interaction and tug safety

6.1 Introduction

6.2 Interaction and shallow water effects

6.3 Tug safety

6.4 Summary and conclusions

6.5 Finally

Chapter 7: Towing equipment

7.1 Introduction

7.2 Additional towing points and gob ropes

7.3 Towing bitts, hooks and winches

7.4 Towline Safety Systems

7.5 Towlines

7.6 Towline handling

7.7 SWL ship’s towing equipment

7.8 Requirements for emergency towing equipment, escorting and pull-back

7.9 New emergency towing concept

Chapter 8: Training and tug simulation

8.1 Reasons for training

8.2 Various training objectives and tools

8.3 How specific training courses can be given

8.4 Assessment of further training needs

8.5 Developments

8.6 Conclusion

Chapter 9: Escort tugs

9.1 The background to escorting

9.2 Studies on escort requirements

9.3 Developments in escorting

9.4 Escorting objectives and tug placement

9.5 Escorting by normal harbour tugs

9.6 Escorting by purpose built tugs

9.7 Escort tug regulations

9.8 Concluding remarks

Chapter 10: Tug developments

10.1 Special developments in the design of tugs

10.2 Autonomous tugs

10.3 Developments in general

Chapter 11: Balancing safety

11.1 Introduction

11.2 Safety

11.3 Risks

11.4 Safety Management Systems

11.5 To summarise

References

Appendix 1: Guidelines for Owners/Operators on Preparing Emergency Towing Procedures

Appendix 2: Safety when handling tugs

Appendix 3: Stability Rules – Escort Tugs

Appendix 4: Standard Guide for Escort Vessel Evaluation and Selection

Appendix 5: Beaufort wind force scale

Index