Сб с 10 до 16

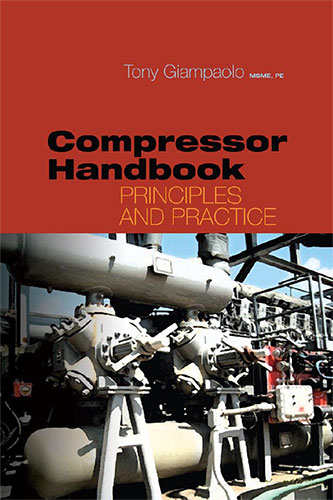

Compressor Handbook: Principles and Practice. Руководство по компрессорам: принципы и практика

-

Основы конструирования приспособлений: методические указания к выполнению расчетно-графических работ

Основы конструирования приспособлений: методические указания к выполнению расчетно-графических работ

-

Основные нештатные режимы судовых электромашин в 2-х частях. Часть 1 (2003 г.) и Часть 2 (2004 г.)

Основные нештатные режимы судовых электромашин в 2-х частях. Часть 1 (2003 г.) и Часть 2 (2004 г.)

-

Машиностроение. Энциклопедия. Том IV-20. Книга 2. Проектирование и строительство кораблей, судов и средств океанотехники

Машиностроение. Энциклопедия. Том IV-20. Книга 2. Проектирование и строительство кораблей, судов и средств океанотехники

This book provides a practical introduction to dynamic and positive displacement compressors, including compressor performance, operation, and problem awareness. In reading this book readers will learn what is needed to select, operate, and troubleshoot compressors. Complete with real-life case histories, the book demonstrates investigative techniques for identifying and isolating various contributing causes, including design deficiencies, manufacturing defects, adverse environmental conditions, operating errors, and intentional or unintentional changes of the machinery process that usually precede failure.

Contents

Preface

Acknowledgements

Introduction

History

General Compressor Theory

Thermodynamics of Compression

Compressor Types

Dynamic Compressors

Axial Compressors

Centrifugal Compressors

Variations in Compressor Design

Positive Displacement Compressors

Blowers

Reciprocating Compressors

Preliminary Selection and Sizing

Screw Compressors

Screw Compressor Control

Effect of Operating Conditions

Effects of Temperature & Pressure

Effects of Compression Ratio

Effects of Specific Heat Ratio

Throughput Control

Speed Control

Suction Throttling Control

Discharge Valve Throttling Control

Recycle Valve Control

Variable Volume Pocket Control

Description of Surge

Surge & Stall

Surge Control

Minimum Flow Control

Maximum Pressure Control

Ratio Control

Vibration

Rotor Response

Sources of Vibration

Valve Requirements

alve Types

alve Trim

Instrument Requirements

Sensor Types

Speed of Response

Detectable Problems

Mechanical Problems

Electrical Problems

Performance Problems

Controlling Reciprocatng and Centrifugal Compressors in Identical Processes

Optimization & Revitalization of Existing Reciprocating Compression Assets

Piston Rod Run-out is a Key Criterion for Recip Compressors

Effect of Pulsation Bottle

Design on the Performance of a Modern

Low-speed Gas Transmission Compressor Piston

Resolution of a Compressor Valve Failure:

A Case Study

Appendix

A1 Compressor Manufacturers

A2 Comparison of Three Types of Compressors

B1 List of Symbols

B2 Glossary of Terms

B3 Conversion Factors

C Gas Processers Suppliers Association Select Curves & Charts

D Classification of Hazardous Atmospheres

E Air/Oil Cooler Specifications Check List

F Cylinder Displacement Curves

G Compressor Cylinder Lubrication

H Troubleshooting Chart

Typical Starting, Operating and Maintenance

Procedures for a Reciprocating Compressor

J Basic Motor Formulas and Calculations

Index